In the early days of the automobile, engine oils were classified by viscosity grade only. By 1930 vehicle manufacturers, however, recognised that there was a need for fixed standards of lubricant quality so that cars and trucks could be sold anywhere world-wide without major modifications or embarrassing failures.

Consequently, lubrication problems started to occur. Oils deteriorated rapidly, wear rates increased, engines failed and performance was generally unacceptable. In the early 1900s it was discovered that the addition of chemicals, referred to as additives, could improve the performance of the mineral base oils.

The American Petroleum Institute (API) then took on the task of setting standards for engine oil. Their first attempt described three oil categories: Regular (straight mineral oil); Premium (mineral oil with oxidation inhibitors) and Heavy Duty (mineral oil with oxidation inhibitors and detergents/dispersants).

However, it was soon realised the requirements for petrol and diesel engines were different and the next API engine oil classifications defined categories for petrol (ML, MM, MS) and diesel (DG, DM, DS) engine oils.

Since then the API Engine Oil Classifications have been revised and updated on various occasions to accommodate improvements in engine designs and the ever increasing stresses placed on engine oil, and more recently to address the concern over the environmental impact of engine emissions. Currently the system includes classifications for spark ignition/petrol engines (“S” series) and for compression ignition/diesel engines (“C” Series). Following is the complete classification for petrol engine oils:

|

CATEGORY |

STATUS |

SERVICE |

|

SA Before 1930 |

Obsolete |

Category for such mild service that these oils required no additives. Originally these oils were classified “API Regular”. |

|

SB 1930 |

Obsolete |

Formulated to provide some antioxidant and anti-scuff properties. Because this category contained no detergent additives, they were also called “non-detergent” oils. |

|

SC 1951 |

Obsolete |

This category provided improved protection against low temperature sludge, deposits, rust, corrosion and wear. Previously known as “API MS”. |

|

SD 1967 |

Obsolete |

Engine tests for this classification also included testing the cleanliness of the positive crankcase ventilation valves during short trips and stop-and-go driving. |

|

SE 1971 |

Obsolete |

Oils designed for this service provided more protection against oil oxidation, high temperature engine deposits as well as rust and oxidation. |

|

SF 1979 |

Obsolete |

Provided improved oxidation stability and anti-wear performance. These oils also offered better protection for smaller, higher revving engines operating at higher temperatures. |

|

SG 1988 |

Obsolete |

Oils meeting this service category provided better control of engine wear, oil oxidation, sludge and varnish for improved engine cleanliness |

|

SH 1993 |

Obsolete |

These oils offered better protection than previous categories in the areas of deposit control, oil oxidation, wear, as well as rust and corrosion. |

|

SJ 1996 |

Current |

This category exhibited different evaporation loss characteristics, plus meeting the requirements of bench tests for wet filterability, gelation index, high temperature foaming and high temperature deposits. SJ also introduced a 0.10 mass % limit on phosphorus content for improved catalyst compatibility. |

|

SL 2001 |

Current |

These oils were formulated to provide better high temperature deposit control and lower oil consumption. |

|

SM 2004 |

Current |

Designed to provide improved oxidation resistance, enhanced deposit protection, better wear protection, and improved low temperature performance over the life of the oil. |

|

SN 2011 |

Current |

Improved high temperature deposit protection for pistons, more stringent sludge control and seal compatibility. Better fuel economy, turbocharger protection and emission control system compatibility. |

API intentionally omitted “SI” and “SK” from the sequence of categories since SI is reserved for Système International d’Unités and SK is the brand name of a South Korean oil company.

For automotive petrol engines, the latest engine oil service category includes the performance properties of earlier categories. If an owner’s manual calls for API SJ, SL or SM oil, API SN oil will provide complete protection.

It is expected that the next API standards for petrol engine oils will be available late 2017/early 2018. Some of these next generation oils will have lower multi-viscosity ratings such as 0W-16 to reduce friction for improved fuel economy. They will also include special additive packages to reduce engine wear. These oils are being developed for high output turbocharged gasoline (petrol) direct injection (GDI) engines. API has not yet confirmed the letter designation for the new oil classification, but it will likely be “SP” (skipping “SO”).

Always consult your vehicle owner’s manual to determine what motor oil you should use, and READ THE LABELS ON THE OIL YOU BUY.

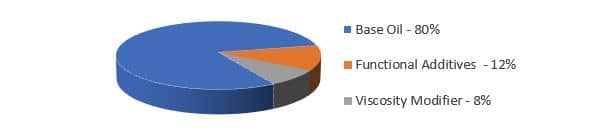

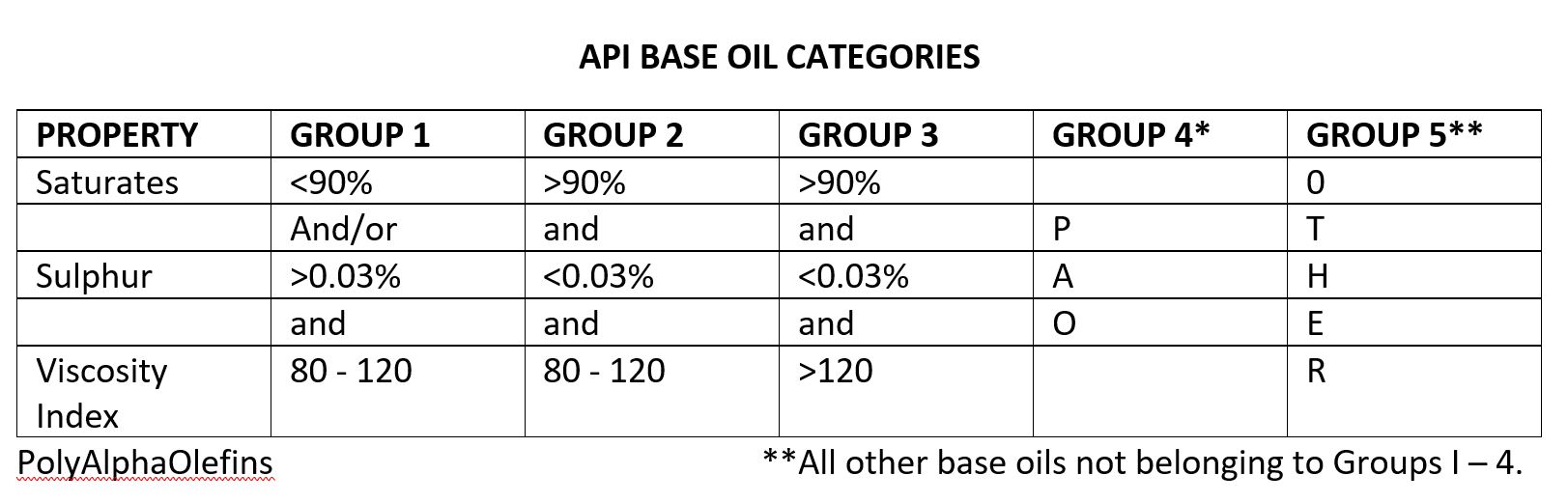

In most instances lubricating oil is a blend of base oil and additives with the base oil content being anything between 70 percent and more than 99 percent depending on the final application of the lubricant. Base oils may be mineral, synthetic or semisynthetic – a mixture of mineral and synthetic stocks. Most lubricating oils used globally (more than 90 percent) are blended using mineral base oils. Feed stocks from a number of streams at crude oil refineries are processed at base oil refineries to produce various viscosity grades of mineral base oils. A typical mineral base oil refinery will have the following units to produce suitable quality base oils:

In most instances lubricating oil is a blend of base oil and additives with the base oil content being anything between 70 percent and more than 99 percent depending on the final application of the lubricant. Base oils may be mineral, synthetic or semisynthetic – a mixture of mineral and synthetic stocks. Most lubricating oils used globally (more than 90 percent) are blended using mineral base oils. Feed stocks from a number of streams at crude oil refineries are processed at base oil refineries to produce various viscosity grades of mineral base oils. A typical mineral base oil refinery will have the following units to produce suitable quality base oils:

p price increases. But why is this and how has Covid-19 affected international lubricant supplies? We operate in a truly global economy and nothing has illustrated this more than the current, ongoing raw material shortages caused by the worldwide pandemic.

p price increases. But why is this and how has Covid-19 affected international lubricant supplies? We operate in a truly global economy and nothing has illustrated this more than the current, ongoing raw material shortages caused by the worldwide pandemic.