In response to OilChat #21 we have received requests to explain the different lubrication regimes (boundary, mixed and hydrodynamic) in more detail.

The regimes of lubrication can be compared to water skiing. Skiers normally start by entering the water with their skis on and holding onto the ski rope. When the skier is ready, the boat starts and the skis begin to move on the sand (boundary lubrication). As the boat accelerates, contact between the skis and sand is reduced (mixed lubrication). When the speed is sufficient, the skier rises out of the water with the front of the skis also out of the water and pointing upwards at an angle. It is this wedge profile between the skis and water that allows the skier to hydroplane on the water (hydrodynamic lubrication).

Before addressing lubrication reg imes, we need to look at how friction and wear occur between moving machine surfaces. These surfaces appear smooth to the naked eye, but they are actually rough and uneven. Tiny peaks called asperities stick out and scrape against asperities on the opposing surface, causing friction and wear. The prime function of a lubricant is to prevent, or at least reduce, wear between surfaces moving on one another. We will endeavour to explain the lubrication of a plain journal bearing in parallel to the skiing analogy above. To enable the shaft to rotate in the bearing on the left, the diameter of the shaft must be less than the inside diameter of the bearing. This creates a wedge similar to the one between the skis and the water.

imes, we need to look at how friction and wear occur between moving machine surfaces. These surfaces appear smooth to the naked eye, but they are actually rough and uneven. Tiny peaks called asperities stick out and scrape against asperities on the opposing surface, causing friction and wear. The prime function of a lubricant is to prevent, or at least reduce, wear between surfaces moving on one another. We will endeavour to explain the lubrication of a plain journal bearing in parallel to the skiing analogy above. To enable the shaft to rotate in the bearing on the left, the diameter of the shaft must be less than the inside diameter of the bearing. This creates a wedge similar to the one between the skis and the water.

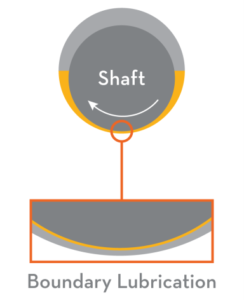

Boundary Lubrication is associated with metal-to-metal contact between moving surfaces. During start-up, t he shaft and bearing asperities in a lubricated system will be in physical contact. The major portion of wear in any machine takes place in this regime. To prevent excessive wear within this regime, lubricants are formulated with additives to form a low-friction, protective layer on the wear surfaces. The base oil of the lubricant acts as a carrier to deposit the additives where they are needed. A suitable viscosity is important to ensure the oil can flow into tight spaces to lubricate the surfaces. The additive chemistry (anti-wear or extreme pressure) used within the lubricant is determined by the application.

he shaft and bearing asperities in a lubricated system will be in physical contact. The major portion of wear in any machine takes place in this regime. To prevent excessive wear within this regime, lubricants are formulated with additives to form a low-friction, protective layer on the wear surfaces. The base oil of the lubricant acts as a carrier to deposit the additives where they are needed. A suitable viscosity is important to ensure the oil can flow into tight spaces to lubricate the surfaces. The additive chemistry (anti-wear or extreme pressure) used within the lubricant is determined by the application.

Mixed lubrication is a transitional regime between the boundary and hydrodynamic lubrication, sharing characteristics of both. Oil molecules are cohesive as well as adhesive and cling to the shaft. As the shaft gains rotational speed, oil is carried into the wedge and starts to lift the shaft, but not sufficiently to separate the two surfaces completely. Mixed lubrication can also occur between surfaces where high loads are encountered, such as when reciprocating pistons slide against cylinder walls. With mixed lubrication, wear protection depends on both the lubricant viscosity, as well as the additives within the oil formulation. A lubricant with a too low viscosity will result in excessive metal-to-metal contact between the shaft and bearing.

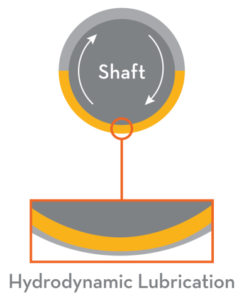

Hydrodynamic lubrication (also known as full film lubrication) occurs when speed and load are such that the oil wedge between the shaft and bearing separates the surfaces completely. This is the ideal condition to avoid friction and wear. In fact, as long as this condition exists, no anti-wear or extreme pressure additives are required, and friction is so low that bearings can operate indefinitely without wear. Any friction remaining comes from the cohesiveness of the oil molecules as they slide past each other during operation. A lubricant with too high viscosity will result in an increase in the oil’s molecular friction. This will in turn increase operational temperatures and energy loss.

The lubrication regimes discussed above pertain to surfaces sliding against each other, such as journal bearings, reciprocating pistons, gears, thrust bearings, chains and guide bearings. In addition to this there is yet another lubrication regime:

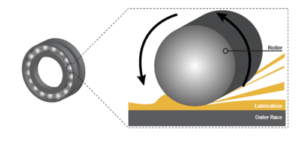

Elastohydrodynamic lubrication is the condition that occurs when a lubricant is introduced between surfaces that are in rolling contact, such as roller bearings. As the oil enters the contact zone between the roller and raceway (by rolling action),  the pressure that develops is sufficient to separate the roller and raceway completely. In fact, the pressure is high enough for the surfaces to deform elastically. The deformation only occurs in the contact zone, and the metal elastically returns to its normal form as the rotation continues, hence the term elastohydrodynamic lubrication. This lubrication regime may be compared to a car tyre aquaplaning on water. It occurs when water on the road accumulates in front of the tyre faster than the weight of the car can push push it out of the way.

the pressure that develops is sufficient to separate the roller and raceway completely. In fact, the pressure is high enough for the surfaces to deform elastically. The deformation only occurs in the contact zone, and the metal elastically returns to its normal form as the rotation continues, hence the term elastohydrodynamic lubrication. This lubrication regime may be compared to a car tyre aquaplaning on water. It occurs when water on the road accumulates in front of the tyre faster than the weight of the car can push push it out of the way.

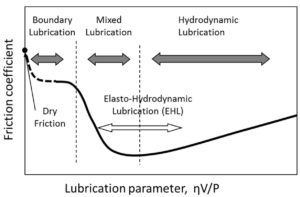

The curve below shows the transition of the lubricating conditions between sliding surfaces. The vertical axis represents the coefficient of friction (an indication of the amount of friction) between sliding surfaces. The horizontal axis is a function of the relative speed between the two surfaces:

The curve clearly illustrates that the coefficient of friction is the highest when speeds are low and boundary conditions prevail. Anti-wear and extreme pressure additives play an important role in this regime. The coefficient of friction is reduced dramatically as speed is increased in the mixed lubrication regime. Once hydrodynamic lubrication is reached, the coefficient of friction is at its minimum. This is because there is no longer any physical contact between the two surfaces owing to the fluid film carrying the entire load. The remaining frictional force is due to the internal friction of the fluid (we mentioned earlier oil molecules are cohesive). When the sliding speed increases further, the coefficient of friction rises again owing to drag (increase in viscous resistance). If the equipment constantly operates in this condition, the viscosity of the oil being used should be reduced. it is therefore evident that oil viscosity is important in the hydrodynamic regime.

Please be aware that the above is a simplified explanation of lubrication regimes and it does not address factors such as Newtonian behaviour, pressure vector distribution, position of shaft in the bearing during the different regimes and bearing parameters.